Introduction

As the demand for electric vehicles and energy storage solutions continues to grow, the efficiency and safety of battery packs are of paramount importance. One crucial aspect of battery pack design is understanding and managing the thermal behavior within the pack. In this article, we delve into the world of Flow Thermal Analysis, shedding light on its significance and practical applications in optimizing battery pack designs.

The Vital Role of Thermal Management in Battery Packs

Efficient thermal management is essential for ensuring the longevity and performance of battery packs. Variations in temperature can impact the lifespan and safety of battery cells. Flow Thermal Analysis provides engineers with critical insights into how heat is generated, transferred, and dissipated within a battery pack, enabling them to make informed design decisions.

● Battery Packs and Efficiency: Understanding the Link with Thermal Management

● Heat Generation in Lithium-Ion Batteries: Causes and Consequences

● Active Cooling Systems: Liquid Cooling and Air-Based Solutions

● Passive Cooling Methods: Heat Sinks, Phase Change Materials, and Insulation

● Temperature Monitoring and Control: Ensuring Optimal Battery Performance

● Impact on Battery Lifespan: How Temperature Influences Degradation

● Safety Considerations: Preventing Thermal Runaway and Overheating Events

● Thermal Management in Electric Vehicles (EVs) and Energy Storage Systems (ESS)

● Advances in Thermal Materials: Improving Heat Dissipation and Regulation

● Future Trends: Innovations in Battery Thermal Management Technologies.

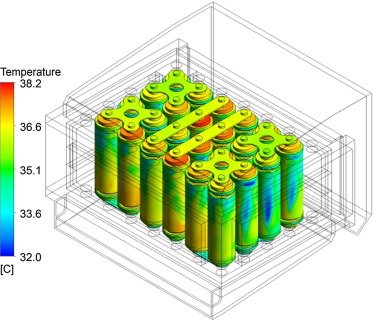

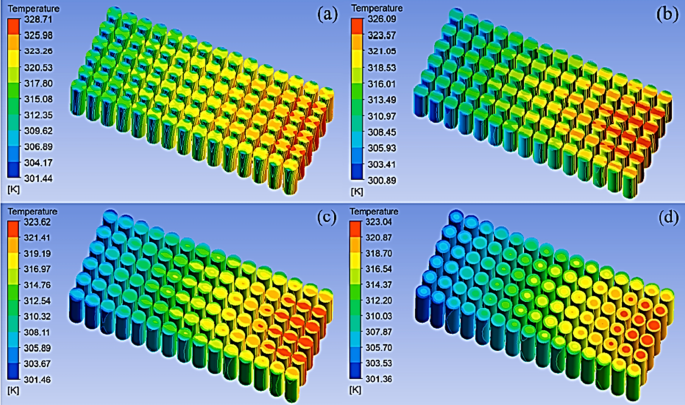

Understanding Flow and Heat Transfer in Battery Packs

Flow Thermal Analysis combines principles of fluid dynamics with heat transfer to simulate the movement of air or coolant within a battery pack. This section provides a detailed explanation of how fluid flow and heat transfer mechanisms interact, influencing the temperature distribution within the pack. We’ll explore the importance of optimizing these processes for enhanced performance

Simulation Techniques: Computational Fluid Dynamics (CFD)

Computational Fluid Dynamics (CFD) is a powerful tool used in Flow Thermal Analysis. It allows engineers to create virtual prototypes of battery pack designs and simulate how air or coolant flows through the pack under various operating conditions. This section delves into how CFD simulations provide critical insights into the thermal behavior of battery packs.

● Introduction to Computational Fluid Dynamics (CFD) in Engineering

● Virtual Fluid Flow Analysis: How CFD Simulations Replicate Real-world Scenarios

● Governing Equations: Navier-Stokes and Continuity Equations in CFD

● Mesh Generation: Dividing the Geometry for Numerical Simulations

● Boundary Conditions: Defining Interaction with Surrounding Environments

● Solvers and Algorithms: Numerical Methods for Solving Fluid Flow Equations

● Validation and Verification: Ensuring Accuracy and Reliability in CFD Results

● Applications Across Industries: Aerospace, Automotive, Energy, and more

● CFD vs. Physical Testing: Advantages and Limitations of Virtual Simulations

● Future Trends: Advances in CFD Technology and its Growing Importance in Engineering

Optimizing Air and Coolant Channels for Effective Cooling

The design of air and coolant channels within a battery pack is crucial for efficient thermal management. Engineers employ various techniques, including channel geometry, placement of cooling elements, and flow rates, to enhance heat dissipation. We’ll explore how Flow Thermal Analysis guides the optimization of these channels, ensuring that the entire pack operates within safe temperature limits.

Cooling Strategies: Air vs. Liquid Cooling

Battery packs can be cooled using either air or liquid cooling methods. Each approach comes with its own set of advantages and considerations. We’ll delve into the pros and cons of both methods, highlighting scenarios where one may be more suitable than the other. Making the right choice can significantly impact the overall thermal performance of the battery pack.

● Air Cooling: Efficient and Cost-Effective Heat Dissipation with Fans or Natural Convection

● Liquid Cooling: Utilizing Coolants to Absorb and Transfer Heat Away from Components

● Thermal Conductivity: Comparing the Heat Transfer Capabilities of Air and Liquid

● Heat Dissipation in High-Performance Systems: The Role of Cooling Solutions

● Space Considerations: How Air and Liquid Cooling Systems Fit into Different Environments

● Noise Levels: Evaluating Acoustic Impact in Air and Liquid Cooling Setups

● Maintenance Requirements: Assessing upkeep needs for Air and Liquid Cooling Systems

● Energy Efficiency: Analyzing Power Consumption and Environmental Impact

● Overclocking and Extreme Performance: Cooling Considerations for Enthusiast Systems

● Application Specificity: Industries and Use Cases Favoring Air or Liquid Cooling Solutions.

Advanced Materials and Thermal Coatings

Innovations in materials and coatings play a critical role in enhancing the thermal performance of battery packs. Heat-resistant materials and coatings can help withstand high temperatures and improve overall efficiency. We’ll discuss how these advancements are leveraged to achieve higher operating temperatures and greater efficiency in battery pack design.

● Cutting-Edge Materials: High-Temperature Alloys, Ceramics, and Composites

● Thermal Conductivity: How Advanced Materials Enhance Heat Dissipation

● High-Temperature Stability: Ensuring Structural Integrity under Extreme Conditions

● Thermal Barriers and Insulation: Protecting Against Heat Transfer in Critical Applications

● Next-Generation Coatings: Nanocomposites and Multilayered Solutions

● Ablative Materials: Sacrificial Layers for Effective Thermal Protection

● Coatings for Specific Environments: Aerospace, Energy, Automotive, and More

● Compatibility with Manufacturing Processes: Integrating Advanced Materials in Production

● Environmental Considerations: Sustainable and Eco-Friendly Thermal Coating Solutions

● Future Prospects: Research and Development in Thermal Materials and Coatings.

Conclusion: Pioneering Efficiency in Battery Pack Design

Flow Thermal Analysis is a cornerstone of modern engineering, enabling engineers to optimize the thermal performance of battery packs. By simulating fluid flow and heat transfer, engineers can make informed design decisions that enhance efficiency and safety. As technology continues to advance, the integration of innovative thermal management concepts promises to reshape the landscape of energy storage solutions, paving the way for a more sustainable and efficient future.