Introduction

Electric motors are the beating hearts of modern machinery, powering everything from electric vehicles to industrial equipment. Ensuring their efficiency and reliability is paramount for sustainable and effective operation. In this article, we delve into the world of electric motor thermal analysis, exploring techniques and strategies to enhance performance and prevent overheating.

The Crucial Role of Thermal Management

Efficient thermal management is essential for electric motors, as they generate heat during operation. Excessive heat can lead to reduced efficiency, decreased lifespan, and even motor failure. Thermal analysis allows engineers to understand how heat is generated and transferred within the motor, enabling them to implement measures for effective cooling and temperature control.

● Defining Thermal Management: Balancing Heat Generation and Dissipation

● Components at Risk: Electronics, Engines, Batteries, and Industrial Machinery

● Preventing Overheating: Importance in Preventing Damage and Ensuring Efficiency

● Cooling Systems: Fans, Heat Sinks, Radiators, and Liquid Cooling Solutions

● Insulation and Thermal Barriers: Minimizing Heat Transfer in Enclosed Systems

● Materials for Heat Dissipation: Conductive Metals, Heat Pipes, and Heat-Resistant Polymers

● Computational Tools: Simulating and Analyzing Heat Flow for Optimal Design

● Energy Efficiency: Impact on Performance and Longevity of Components and Systems

● Safety Considerations: Mitigating Fire Hazards and Ensuring Worker Well-being

● Environmental Impact: Eco-Friendly Cooling Solutions for Sustainable Operations.

Heat Generation Mechanisms in Electric Motors

Understanding how heat is generated within an electric motor is the first step in effective thermal analysis. This section provides a detailed explanation of the key mechanisms that contribute to heat generation, including resistive losses, magnetic losses, and mechanical losses. By comprehending these processes, engineers can identify areas for optimization.

● Resistive Heating: Resulting from Electrical Resistance in the Motor Windings

● Iron Losses (Hysteresis and Eddy Current Losses): Due to Magnetic Field Changes

● Mechanical Friction and Windage Losses: From Moving Parts and Air Interaction

● Copper Losses: Arising from Electrical Current Flow in the Motor Windings

● Core Losses: Combining Iron and Copper Losses, Reflecting Total Losses in the Core

● Inverter Losses: Conversion of DC to AC and Associated Heat Generation

● Variable Load: Increased Heat Generation at Higher Loads and Speeds

● Ambient Temperature: External Environment Affecting Heat Dissipation

● Duty Cycle: Continuous vs. Intermittent Operation Impacting Heat Buildup

● Cooling Systems: Fans, Liquid Cooling, or Heat Sinks to Manage Motor Temperature.

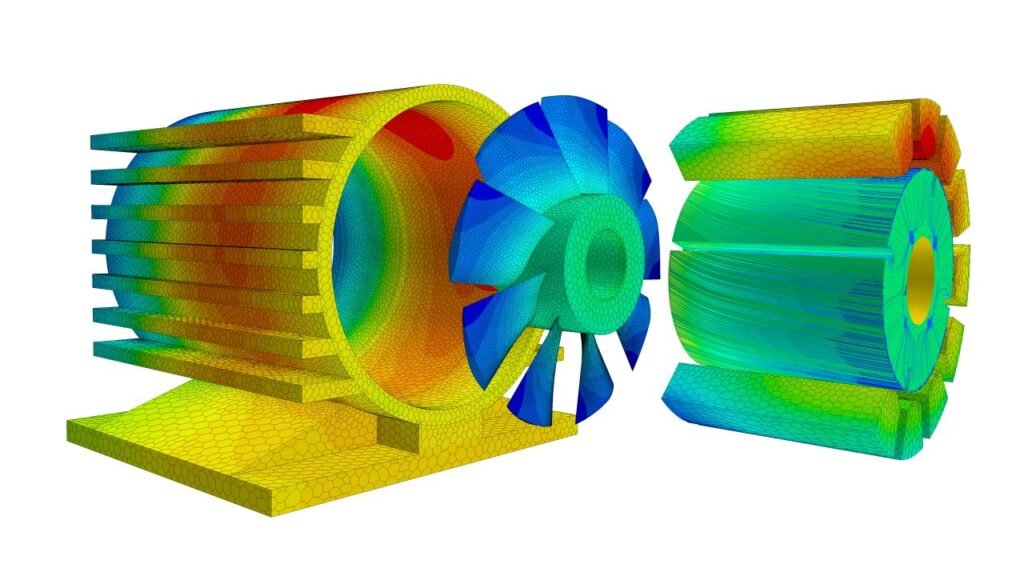

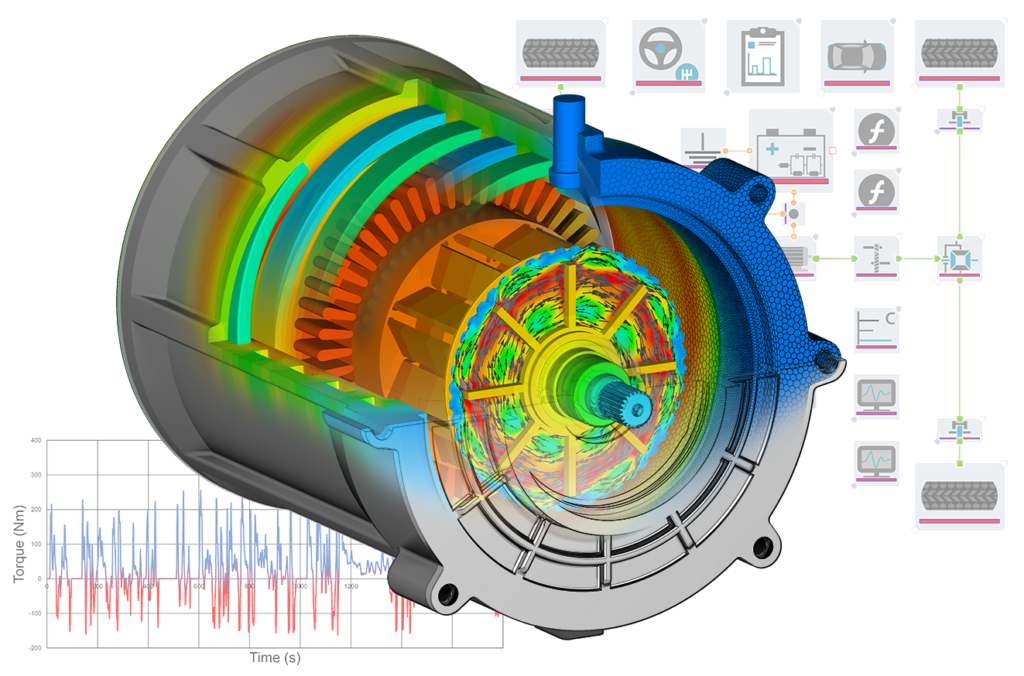

Finite Element Analysis (FEA): A Powerful Tool for Thermal

Analysis

Finite Element Analysis (FEA) is a computational technique that simulates the behavior of complex systems, including heat transfer within electric motors. FEA models the motor’s geometry and material properties to predict temperature distributions under various operating conditions. This section explores how FEA enables engineers to conduct detailed thermal analyses and make informed design decisions.

● Understanding Finite Element Analysis (FEA) in Engineering and Design

● Thermal Analysis in FEA: Predicting Temperature Distribution and Heat Transfer

● Importance of FEA in Evaluating Thermal Performance of Components and Systems

● Boundary Conditions: Specifying Thermal Loads, Convection, and Radiation Effects

● Material Properties: Defining Thermal Conductivity, Specific Heat, and Thermal Expansion

● Heat Generation Simulation: Modeling Sources of Heat Within the Component

● Transient vs. Steady-State Analysis: Analyzing Temperature Changes Over Time

● Practical Applications: FEA for Thermal Management in Electronics, Structures, and More

● FEA Software: Utilizing Tools like ANSYS, COMSOL, and Abaqus for Thermal Analysis

● Accuracy and Validation: Correlating FEA Results with Experimental Data for Verification

Cooling Methods: Air vs. Liquid Cooling

Electric motors can be cooled using either air or liquid cooling methods, each with its own advantages and considerations. Air cooling relies on airflow over the motor’s surface to dissipate heat, while liquid cooling uses a coolant to absorb and transfer heat away from the motor. We’ll delve into the pros and cons of each approach and highlight scenarios where one may be more suitable than the other.

Optimizing Cooling Systems

Regardless of the cooling method used, the design of the cooling system is critical for effective thermal management. This section explores strategies for optimizing cooling systems, including the design of heat exchangers, the selection of coolant flow rates, and the placement of cooling channels. By fine-tuning these elements, engineers can ensure that the motor operates within its safe temperature range.

● Cooling Systems: Vital for Maintaining Optimal Operating Temperatures in Machinery

● Design Considerations: Balancing Cooling Efficiency with Energy Consumption

● Efficient Heat Exchange: Maximizing the Transfer of Heat Away from Components

● Adequate Airflow: Ensuring Unobstructed Paths for Cool Air to Reach Hotspots

● Proper Ventilation: Designing Enclosures to Facilitate Heat Dissipation

● Heat Sinks and Radiators: Enhancing Surface Area for Improved Heat Dissipation

● Selection of Coolants: Factors to Consider for Effective Heat Transfer Mediums

● Active Cooling Methods: Fans, Pumps, and Blowers for Forced Air Circulation

● Monitoring and Control Systems: Sensors and Feedback Loops for Temperature Regulation

● Regular Maintenance: Cleaning and Inspecting Cooling Components for Optimal Performance.

Advanced Materials and Thermal Coatings

Innovations in materials and coatings play a vital role in enhancing the thermal performance of electric motors. Heat-resistant materials and coatings can help withstand high temperatures and improve overall efficiency. We’ll discuss how these advancements are leveraged to achieve higher operating temperatures and greater efficiency in electric motors.

● Cutting-Edge Materials: Alloys, Composites, and Ceramics Engineered for High Temperatures

● Heat Resistance and Thermal Conductivity: Key Properties in Advanced Material Selection

● Thermal Barrier Coatings (TBCs): Insulating Surfaces from High Temperatures

● Ablative Materials: Sacrificial Layers that Dissipate Heat in Extreme Environments

● Nanocomposites: Harnessing Nanotechnology for Enhanced Thermal Efficiency

● Multilayered Coatings: Strategic Application of Materials for Maximum Protection

● Aerospace Applications: Lightweight Materials for Spacecraft and Hypersonic Vehicles

● Energy Industry: Materials and Coatings for Efficient Power Generation and Turbines

● Thermal Protection Systems in Aerospace: Safeguarding Vehicles during Reentry

● Future Prospects: Research and Development in Advanced Thermal Materials and Coatings.

Conclusion: Pioneering Efficiency through Thermal Analysis

Electric motor thermal analysis is a cornerstone of modern engineering, enabling engineers to optimize performance, prevent overheating, and extend the lifespan of motors. By employing techniques like FEA and carefully considering cooling methods and materials, engineers can push the boundaries of efficiency and reliability in electric motor design. As technology continues to advance, these thermal analysis strategies will play a central role in shaping the future of electric mobility and industrial applications.