Introduction

In the pursuit of cleaner and more efficient engines, Exhaust Gas Recirculation (EGR) systems have emerged as a crucial technology. Understanding how heat is transferred within these devices is essential for optimizing their performance. In this article, we delve into the realm of Conjugate Heat Transfer (CHT) and its application in EGR devices, shedding light on its significance and practical implications.

The Role of EGR Systems in Engine Efficiency

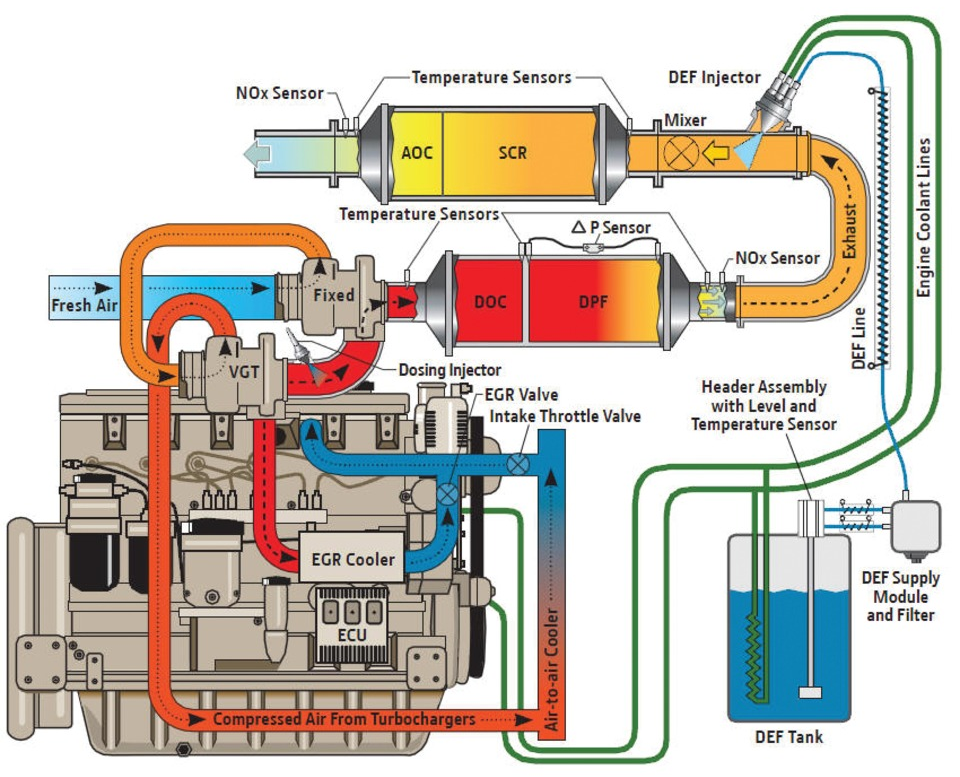

Exhaust Gas Recirculation (EGR) systems play a vital role in reducing emissions and improving fuel efficiency in internal combustion engines. By reintroducing a portion of exhaust gases into the combustion chamber, EGR systems lower peak combustion temperatures, thereby minimizing the formation of harmful nitrogen oxides (NOx). We explore the intricacies of EGR systems and their impact on engine performance.

● Introduction to EGR Systems: Exhaust Gas Recirculation in Internal Combustion Engines

● Emissions Reduction: Lowering Nitrogen Oxide (NOx) Emissions for Environmental Compliance

● Recirculating Exhaust Gas: Reintroducing a Portion of Exhaust Back into the Combustion Chamber

● Combustion Temperature Control: Diluting Air-Fuel Mixture to Lower Peak Combustion Temperatures

● Reduction of NOx Formation: Inhibiting Oxygen-Rich Regions in the Combustion Process

● Improved Fuel Efficiency: Balancing EGR Rates to Optimize Fuel Consumption

● Advanced EGR Technologies: High Pressure, Low Pressure, and Hybrid EGR Systems

● Engine Calibration: Fine-Tuning EGR Rates for Optimal Performance and Emissions

● EGR Cooler: Lowering Recirculated Gas Temperature for Enhanced Efficiency

● Regulatory Compliance: Meeting Emission Standards and Regulations with EGR Systems.

Conjugate Heat Transfer: The Key to Efficient EGR Systems

Conjugate Heat Transfer (CHT) is a computational technique used to analyze the simultaneous heat transfer within solids and fluids. In the context of EGR devices, CHT allows engineers to model the exchange of heat between the hot exhaust gases and the surrounding components, such as EGR coolers and pipes. This section provides an in-depth understanding of how CHT is applied in the analysis and optimization of EGR systems.

● Understanding Conjugate Heat Transfer (CHT) in Engineering and Thermodynamics

● Interactions of Fluid Flow and Heat Transfer in Complex Geometries

● Application in EGR Systems: Managing Heat Exchange between Exhaust Gas and Components

● Combining Fluid Dynamics and Thermal Analysis for Accurate EGR System Design

● Computational Tools: Utilizing CFD and FEA for Conjugate Heat Transfer Simulations

● Material Considerations: Selecting Heat-Resistant Alloys and Coatings for EGR Components

● Cooling Strategies: Incorporating Heat Exchangers and Coolant Circulation in EGR Systems

● Optimizing EGR System Performance: Balancing Heat Transfer and Flow Characteristics

● Durability and Reliability: Ensuring Longevity of EGR Components under High Temperatures

● Environmental Impact: EGR Systems as a Key Component in Reducing Vehicle Emissions.

CHT Modeling: Simulating Real-World Conditions

Accurately simulating heat transfer in EGR devices requires a detailed understanding of the complex interactions between fluid flow and solid components. Computational fluid dynamics (CFD) software, coupled with CHT models, enables engineers to create virtual prototypes and simulate real-world operating conditions. We delve into the process of setting up and running CHT simulations for EGR systems.

● Conjugate Heat Transfer (CHT): Coupling of Fluid Flow and Heat Transfer Analyses

● Realistic Simulation: Replicating Physical Phenomena in Complex Engineering Systems

● Thermal Interactions: Understanding Heat Transfer within Solid Components and Fluids

● Multidisciplinary Approach: Combining CFD and FEA for Comprehensive CHT Analysis

● Boundary Conditions: Defining Thermal Properties and Constraints for Accurate Modeling

● Material Properties: Specifying Thermal Conductivity, Specific Heat, and Density for Components

● Transient vs. Steady-State Analysis: Assessing Temperature Changes Over Time

● Validation and Verification: Corroborating CHT Simulations with Experimental Data

● Practical Applications: Aerospace, Automotive, Electronics Cooling, and Energy Systems

● Future Trends: Advancements in CHT Modeling for Enhanced Engineering Design.

EGR Cooler Design: Balancing Efficiency and Durability

EGR coolers are critical components in EGR systems, tasked with lowering the temperature of recirculated exhaust gases before they re-enter the combustion chamber. Designing an effective EGR cooler requires a meticulous balance between heat exchange efficiency, pressure drop, and structural integrity. This section explores how CHT analysis guides the optimization of EGR cooler design.

● EGR Cooler Function: Lowering Exhaust Gas Temperature before Recirculation into Combustion Chamber

● Material Selection: Heat-Resistant Alloys for Optimal Performance in High-Temperature Environments

● Thermal Efficiency: Maximizing Heat Exchange Between Exhaust Gas and Coolant

● Flow Path Design: Ensuring Proper Distribution and Passage for Efficient Cooling

● Corrosion Resistance: Coatings and Materials to Withstand Harsh Exhaust Conditions

● Size and Geometry: Balancing Compact Design with Sufficient Cooling Surface Area

● Durability Considerations: Materials and Design Features for Long-Lasting Performance

● Heat Transfer Enhancement Techniques: Fins, Tubes, and Surface Treatments for Improved Efficiency

● Computational Modeling: Utilizing CFD to Optimize EGR Cooler Performance and Design

● Testing and Validation: Real-World Verification of EGR Cooler Efficiency and Reliability.

Thermal Stress Analysis: Ensuring Reliability

In addition to optimizing heat transfer, it’s imperative to consider the structural integrity of EGR components. Thermal stress analysis, a subset of CHT, assesses how temperature variations induce mechanical stresses in materials. We uncover how engineers use CHT simulations to ensure that EGR devices can withstand the thermal loads they experience during operation.

Future Trends: Advancements in EGR Technology

As emission standards continue to evolve, so too will EGR technology. This section provides a glimpse into future trends, including advancements in materials, coatings, and innovative designs that promise to further enhance the efficiency and effectiveness of EGR systems.

● Enhanced Integration with Aftertreatment Systems for Synergistic Emissions Reduction

● Smart EGR Systems: Incorporating Sensors and Controls for Dynamic Performance

● Electro-Hydraulic EGR Systems: Next-Generation Actuation for Precision Control

● Hybrid EGR Systems: Combining High and Low-Pressure EGR for Optimal Efficiency

● Thermal Management Integration: EGR Systems as Part of Overall Engine Cooling Strategy

● Advanced Materials: Heat-Resistant Alloys and Coatings for Extended EGR Component Life

● Predictive Analytics: AI and Machine Learning for Optimal EGR System Operation

● Compact and Modular EGR Solutions for Improved Packaging and Installation Flexibility

● EGR in Hybrid and Electric Powertrains: Tailoring EGR to Suit Diverse Propulsion Systems

● Innovations in EGR Cooling: Advanced Coolant and Heat Exchange Technologies.

Conclusion: Pioneering Efficiency in Engine Technology

Conjugate Heat Transfer (CHT) has emerged as a powerful tool in the quest for cleaner and more efficient engines, particularly in the realm of Exhaust Gas Recirculation (EGR) devices. By ever raging CHT simulations, engineers can optimize the design and performance of EGR systems, striking a balance between emissions reduction and engine efficiency. As we look to the future, continued advancements in CHT technology promise to revolutionize the way we approach engine development, ushering in a new era of cleaner and more sustainable transportation.