Finite Element Analysis (FEA)

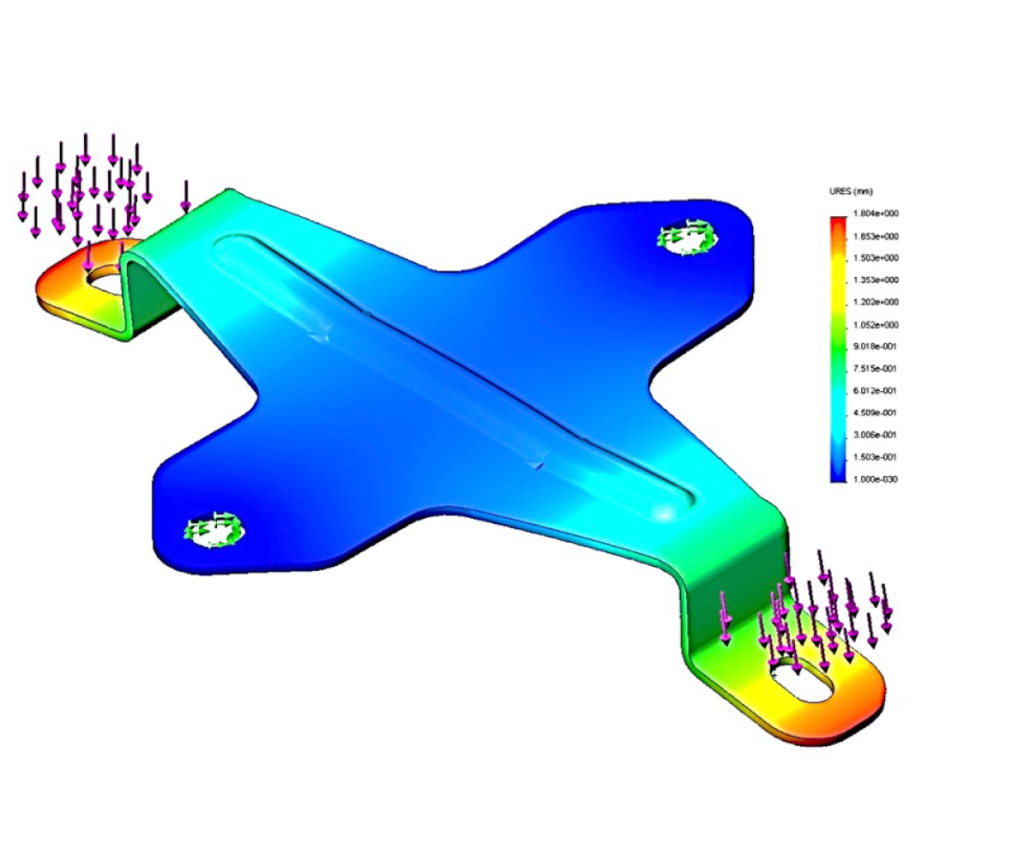

FEA has revolutionized the way engineers design products by enabling them to analyze and optimize structures with complex geometries and variable material properties. It is widely used in various engineering domains, including the automotive, aerospace, power generation, and manufacturing industries, to improve product performance and reliability.

FEA accurately predicts how components will respond to thermal and structural loads, allowing engineers to verify design integrity and identify critical locations without the need to physically build the component. This saves time and costs while improving product quality and reliability.

As the demand for better product quality and reliability at reduced costs increases, FEA has become a vital tool for organizations to develop and enhance existing products. It also provides a competitive edge in global markets, enabling companies to stay ahead of their competitors.

FEA Capabilities

- Investigation of Linear Analysis

- Investigation ofNonlinear Analysis

- Investigation of Static Analysis

- Investigation of Dynamic Analysis

- Behaviour of Thermal Analysis

- Behaviour of Buckling Analysis

- Behaviour of Fatigue Analysis

Advantages of FEA

- Provides accurate and detailed information about the behavior of structures and systems under various loading conditions.

- Enables engineers to optimize designs and identify potential failure points before the manufacturing process begins.

- Reduces the need for physical prototyping, which can save time and money.

- Allows for the evaluation of complex geometries and materials that would be difficult to analyze using traditional methods.

- Helps to minimize material usage and weight while maintaining structural integrity.

- Provides a visual representation of stress and strain distributions within a structure, which can aid in understanding the behavior of the system.

- Can be used to simulate a range of physical phenomena, including heat transfer, fluid flow, and electromagnetic fields.

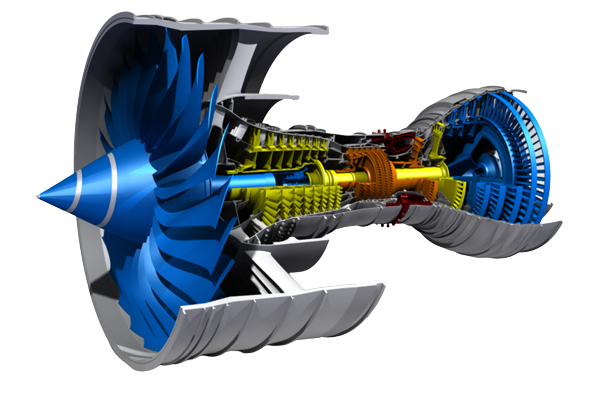

AEROSPACE

The aerospace industry places a high priority on delivering safe, reliable, and durable products. This requires adherence to stringent safety and regulatory norms, which can vary depending on the application and performance requirements of individual components. This variability increases the complexity of the design process, especially when it comes to integrating components into a single system. To handle these complexities and deliver continuous improvements in a shorter lead time, aerospace designers use advanced modeling and simulation tools such as FEA.

FEA has become an indispensable tool in aerospace design over the past few decades. It is widely used for structural analysis of various aircraft structures, including wings, racks, overhead cabins, and seats. It is also used for electronics system cooling analysis, modal analysis, landing gear analysis, engine and nacelle component analysis, and fuel and air handling systems component analysis. By using FEA to simulate and analyze these components and systems, designers can identify and address potential issues early in the design process, leading to better product quality and improved performance.

With our expertise, we can assist you in:

•FEA Simulations to study Structural analysis various aircraft structures (example: wings, rack cabins, overhead cabins, seats, etc.), electronics system! cooling analysis, model analysis, landing gear analysis, engine & nacelle component analysis and fuel & air handling systems.

•Helicopter and Drone components (Rotor, Blades, Engine etc) study to determine its stress and deformations FEA analysis.

•Fighter aircraft Thermal stress deformations.

•Fluid-Structure interaction during water landing conditions to determine force on aircraft landing in water.

•Fatigue Analysis in component level like turbine, Compressor, landing gear door etc.

•Crash Analysis under dynamic loading conditions.

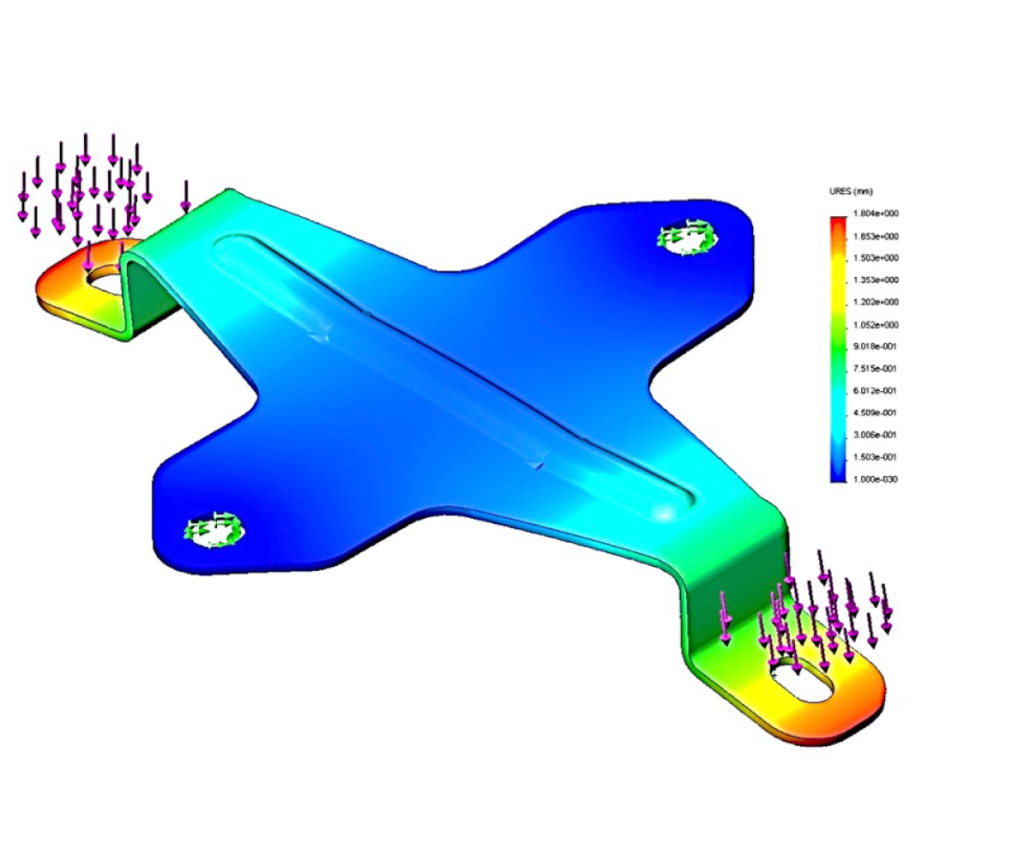

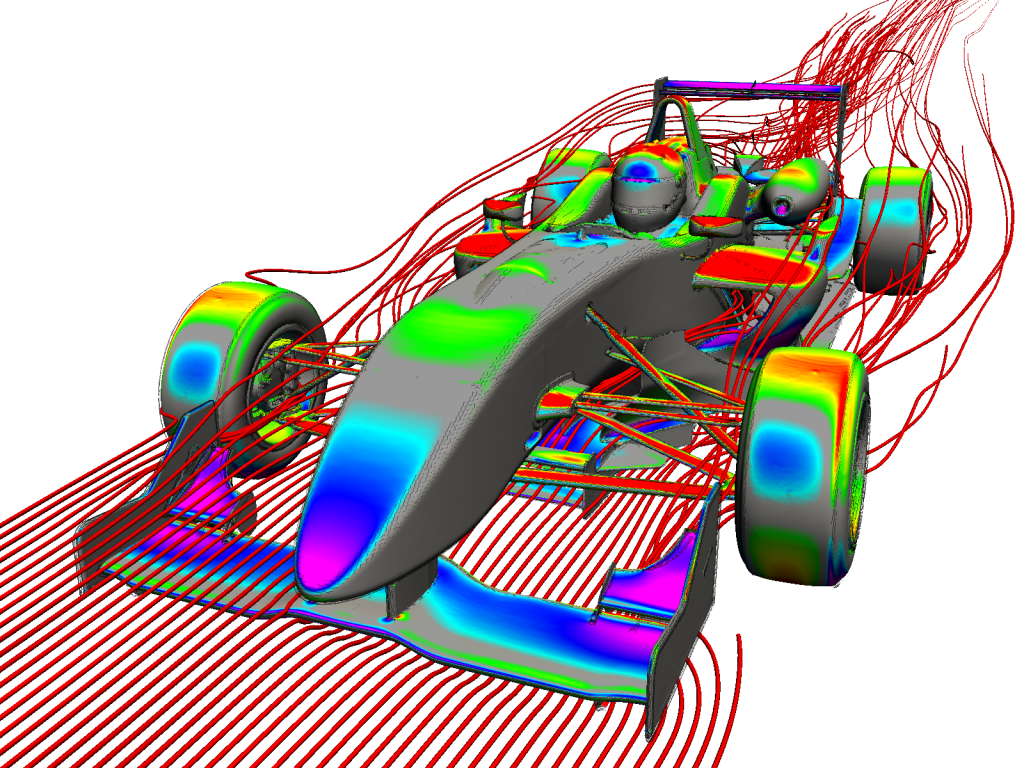

AUTOMOTIVE

FEA has various applications in the automotive industry such as structural analysis of car bodies, suspension systems, engine components, airbag deployment analysis, crash analysis, and impact analysis. FEA helps in identifying the weak points of a design and assists in making informed decisions during the design process. It also helps in optimizing the design for weight reduction, cost-effectiveness, and performance. Furthermore, FEA is useful for predicting and minimizing the effects of environmental factors like temperature, humidity, and vibration on the vehicle’s performance. In summary, FEA plays a vital role in the design and development of high-quality and reliable vehicles with shorter lead times, giving automotive companies a competitive edge in the market

Services We provide:

• Linear or Non-Linear FEA Simulation for vehicle Structure Interaction.

• Vehicle Structural/Model/Harmonic Analysis.

• Crash Analysis.

• FEA to reduce the risk of Creep & Fracture.

• Fluid Structure Interactions applications on vehicle dynamics.

• Car chassis stiffness and rigidity FEA to reduce structure failure.

DEFENCE APPLICATIONS

(FEA) Simulation to determine various parameters like stress & deformation, thermal load effect on bending of structure, mines and tanks ballistic force and acoustic analysis, missiles and fighter aircraft strength, fatigue & crash analysis, helicopter and drone blades flexibilities and its strength analysis etc.

FEA simulation can be used to determine various parameters such as stress and deformation, thermal load effects, ballistic forces, acoustic analysis, strength, fatigue, crash analysis, and more for a wide range of applications, including those you mentioned. For stress and deformation analysis, FEA can be used to simulate the behavior of a structure under different loading conditions and predict its response to external forces, allowing engineers to optimize designs and ensure the safety and reliability of the structure. For thermal load effects on bending of structures, FEA can be used to simulate temperature changes and thermal gradients in a structure, and predict how these changes will affect the structure’s bending behavior, allowing designers to optimize the material selection and geometry of the structure for specific temperature regimes. For ballistic force analysis of tanks and mines, FEA can be used to simulate the impact of projectiles on the structure, predict the deformation and stress response, and optimize the armor design for maximum protection.

ELECTRIFICATION FEA ANALYSIS

Finite Element Analysis (FEA) is a powerful computational tool used to analyze the behavior of physical systems under various conditions. In the context of electrical vehicles, FEA can be used to analyze and optimize the performance of various components such as batteries, motors, and power electronics. One key area where FEA is used in electric vehicles is in the design and analysis of batteries. FEA can be used to model the electrochemical behavior of battery cells, predict the temperature and stress distribution in the battery pack, and optimize the design for weight, cost, and performance.

FEA can also be used to analyze the performance of electric motors, which are a critical component of electric vehicles. By modeling the magnetic fields and electrical currents in the motor, FEA can predict the torque, power, and efficiency of the motor, and optimize the design for maximum performance. Power electronics, such as inverters and converters, are also important components in electric vehicles, and FEA can be used to analyze and optimize their performance. By modeling the electrical and thermal behavior of these components, FEA can predict their efficiency, reliability, and lifetime.

Overall, FEA plays a critical role in the design and optimization of electrical vehicles, helping engineers to improve their performance, reduce their cost, and increase their reliability.

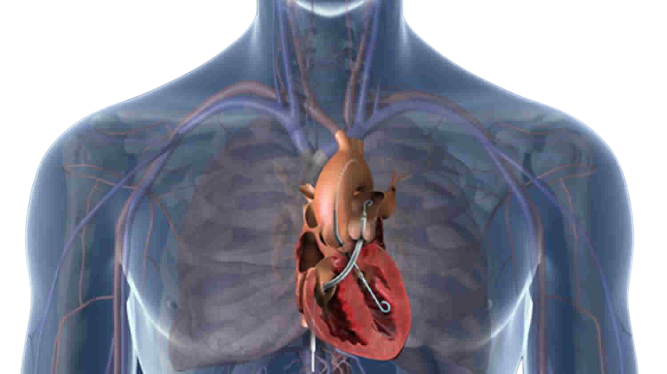

Medical Health Care

The determination of stiffness and rigidity of a medical device such as a nano or micro channel cardiovascular or respiratory device can be important for ensuring its structural integrity and functional performance. Pipe stress and deformation analysis can be a useful tool for evaluating the mechanical behavior of such devices.

To perform pipe stress and deformation analysis, you would typically use finite element analysis (FEA) software. FEA allows you to simulate the mechanical behavior of a structure under different loading conditions and can provide insights into its stiffness, rigidity, and other important properties.

To begin the analysis, you would first create a 3D model of the device using CAD software or other modeling tools. This model would include all relevant features and details, such as the dimensions and shapes of the channels, the material properties of the device, and any external loads or boundary conditions

OIL & GAS

FEA is extensively used in the Oil & Gas industry for design optimization, failure analysis, and structural integrity assessment of various components. It is used in the analysis of complex geometries and loading conditions of equipment such as pressure vessels, heat exchangers, pipelines, and storage tanks. FEA provides insights into the performance of these components, enabling engineers to optimize design parameters such as material selection, thickness, and orientation. It also aids in predicting the behavior of equipment under different operating conditions, thereby providing a better understanding of the equipment’s structural integrity. FEA is also used in the simulation of fluid flow and heat transfer, which is critical for the proper functioning of the equipment. The use of FEA in the Oil & Gas industry has led to the development of more efficient and reliable equipment, which is essential for the safe and sustainable operation of oil & gas plants.

FEA Oil and Gas Services

• Static structure, Modal Analysis, Frequency response and Vibrations on various structure (Wall, screw, bolts etc) of big oil tanks. Fluid pressure calculations will be based on oil sloshing or due to seismic effect.

• FEA on Pipe Stress analysis as per ASME B31.1 & ASME B31.3 for different pipe network including plant room, networks, and oil and gas etc.

• Simulation Support design for oil and gas pipelines to withstand sustained, operating, occasional loads ( Seismic loads and wind loads) as per ASCE & BS 5950 Standards Pulsation & Mechanical Analysis of Pipeline (As per API 618, and API 674 standards) .

• Seismic design of oil and gas piping network inside a building Solve complex engineering challenges using mathematical modelling and numerical simulations.

REAL STATE (BUILDING AND CONSTRUCTION)

• Under Ground Tunnelling: FEA/Calculations on IBC projects for Seismic, Wind & Snow and Design for Chillers, AHUs, Fuel Tank, Gensets Enclosure, Skids etc.

• Seismic Analysis of Large Vessels (Tank with Floating Roof).

•Static Analysis of any building or bridge or dams under its own as weight or wind pressure can affect its structure failure and determining its strength to standalone conditional Dynamic FEA Analysis for any building or bridge or dams under the rapid changing loading like Earth quake or strong wind gust like cyclone, Tsunamis etc.

• Buckling Analysis of beams or pillars or steel rods for preventing structure failure.

• Fatigue Analysis under repeated loading and unloading conditions so that behavior of structure failure can be determined.

• Seismic Analysis used to determine potential point of failures and to determines the design solution that can withstand seismic loads on the stand alone structure like commercial tech buildings, bridge.

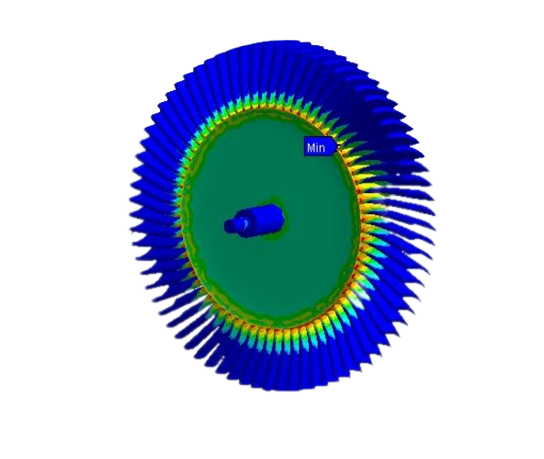

Turbomachinery and other rotating Machinery:

FEA can be used to study and optimize the design of turbomachinery components such as rotors, stators, seals, and other rotating systems. By simulating the performance of these components under different operating conditions, FEA can predict potential failure modes, identify areas of high stress or vibration, and determine the expected lifespan of the turbomachinery. This information can then be used to optimize the design of the components, leading to improved efficiency, reduced emissions, and cost savings. Pansim’s FEA services can help to address these challenges in the turbomachinery industry.

Finite element analysis (FEA) is another technique that can be used to analyze and optimize the performance of Turbo Machinery components. Here are some key points about Turbo Machinery FEA:

FEA can be used to analyze the structural integrity of Turbo Machinery components, such as blades, vanes, and impellers. This analysis can help to identify potential areas of stress concentration, deformation, and fatigue, allowing for improvements to be made to the component design.

FEA simulations can be used to optimize the design of Turbo Machinery components, such as the shape of the blades or the thickness of the walls. This optimization can lead to better performance, longer lifespan, and reduced maintenance costs.

FEA services can be used to simulate the dynamic behavior of Turbo Machinery components under different operating conditions, such as different speeds or loads. This can help to identify potential issues with the operation of the machine and to optimize its design for better performance and efficiency.

FEA can be used to study the effects of different materials on the performance of Turbo Machinery components. This can help to identify the optimal materials for different components, improving their reliability, durability, and performance.

FEA can be used to simulate the thermal behavior of Turbo Machinery components, such as the heat transfer between different parts of the machine. This can help to optimize the cooling systems for the machine, improving its performance and efficiency.