Introduction

Long tunnels, whether for transportation or ventilation purposes, require careful design considerations to ensure efficient airflow and safety for users. Computational Fluid Dynamics (CFD) analysis is a crucial tool in optimizing the ventilation and aerodynamic performance of these tunnels. In this article, we will explore the application of CFD analysis in designing and managing airflow within long tunnels, ultimately ensuring a safe and comfortable environment for users.

Understanding CFD Analysis for Long Tunnels

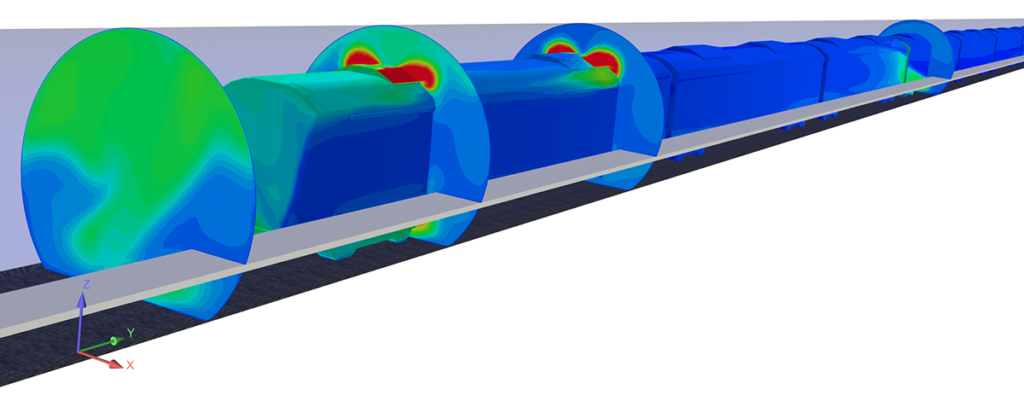

Computational Fluid Dynamics (CFD) is a simulation technique used to study the behavior of fluids and gases within a specified environment. In the context of long tunnels, CFD analysis involves creating a virtual model of the tunnel and simulating the flow of air, smoke, and other substances within it. This allows engineers to identify areas of low air quality, optimize ventilation systems, and enhance safety measures.

Benefits of CFD Analysis for Long Tunnels

Optimized Ventilation Systems: CFD analysis allows engineers to visualize and analyze the airflow patterns within the tunnel. This insight helps in designing and positioning ventilation systems to efficiently control air quality.

Smoke Control and Evacuation Planning: In case of emergencies, CFD analysis can simulate the dispersion of smoke and gases, aiding in the development of effective evacuation plans and the placement of emergency equipment.

Temperature Regulation: Understanding how heat is distributed within the tunnel is crucial for maintaining a comfortable environment. CFD analysis can help fine-tune ventilation and cooling systems to ensure even temperature distribution.

Wind and Pressure Studies: For tunnels exposed to external elements, CFD analysis can simulate the effects of wind and pressure, enabling engineers to design structures that can withstand these forces.

Energy Efficiency: By optimizing ventilation systems and airflow patterns, CFD analysis can lead to reduced energy consumption for ventilation and cooling processes.

Steps in Conducting CFD Analysis for Long Tunnels:

Model Creation: Engineers create a detailed 3D model of the tunnel, including components like the road or rail system, ventilation openings, and emergency exits.

Boundary Conditions: Parameters such as initial airflow conditions, temperature, and presence of pollutants are defined. These conditions simulate different scenarios within the tunnel.

Meshing: The 3D model is divided into smaller elements (mesh) to facilitate numerical calculations. This step is crucial for accurate simulation results.

Simulation and Analysis: The CFD software performs simulations based on the defined parameters. Engineers analyze the results to identify areas of improvement.

Iterative Process: Design modifications are made based on the analysis, and the CFD simulation is run again. This process is repeated until the desired level of optimization is achieved.

Conclusion

CFD analysis is an indispensable tool in the design and operation of long tunnels. By simulating airflow patterns, smoke dispersion, and temperature distribution, engineers can make informed decisions that lead to improved ventilation, safety, and energy efficiency. This approach not only benefits the users of the tunnel but also contributes to the overall effectiveness and sustainability of transportation and infrastructure projects. Embracing CFD analysis in tunnel design is a significant step towards creating safer and more efficient transportation systems.