8-Weeks CAD/CAM Training

CAD/CAM Mentorship Program

₹19,999 + GST

- Industry led CAD/CAM Training with 12+ Years Experienced Trainers

- SolidWorks, Fusion 360, AutoCAD, Mastercam, NX CAM (student’s choice)

- 1 on 1 Career Guidance

- Live Industry Project

- Resume Building + Mock Interview

- Industry Standard Certificate

- BE | B. Tech Final Year Assistance

- ME | M. Tech Thesis Assistance

- Research Paper Publication Assistance

- Guaranteed Job Internship for Top Students

Our Trainee got Recruited in

Course

Course Overview

Title: CAD/CAM Mastery for Final Year Projects & Industry Readiness

Duration: 8 Weeks | Mode: Online + 1:1 Mentorship + Live Demos

Tools Covered: SolidWorks, Fusion 360, AutoCAD, Mastercam, NX CAM (student’s choice)

Support: 2 Weekly Live Sessions + Practice Task Reviews + Chat Assistance

Program Highlights:

A hands-on, project-driven mentorship designed to equip BE/BTech students with end-to-end CAD/CAM skills. From 3D modeling and GD&T-compliant drafting to CAM toolpath generation and G-code programming, master the tools and workflows used in automotive, aerospace, and product design industries. Includes CNC simulation, report writing, and viva prep to deliver a polished final year project.

Why enrol in the Program?

🛠️ Industry-Standard CAD/CAM Expertise

Gain proficiency in SolidWorks, Fusion 360, and Mastercam—tools dominating automotive, aerospace, and manufacturing roles.

👩🏫 Expert-Led Mentorship

Learn from CAD/CAM professionals with 5+ years of industry experience. Get personalized feedback on designs, toolpaths, and reports.

📂 Complete Final Year Project

Walk away with a submission-ready portfolio: 3D models, technical drawings, G-code files, and a professionally formatted report.

🏭 End-to-End Manufacturing Pipeline

Transition seamlessly from design (CAD) to manufacturing (CAM), mastering DFM principles, GD&T, and CNC programming.

🚀 Career Acceleration

Stand out in job interviews with hands-on CAM simulations, ANSI/ASME drafting skills, and a certificate of mentorship completion.

Perfect For

-

-

BE/BTech & ME/MTech Final Year Students needing guidance to execute a standout CAD/CAM project (jigs, molds, automotive parts, etc.).

-

Aspiring Design/Manufacturing Engineers aiming to add CAD modeling, CAM programming, or CNC expertise to their resume.

-

Career Changers (e.g., civil to mechanical) seeking hands-on exposure to product design and machining workflows.

-

Students with Limited Lab Access wanting to master virtual CNC simulations and GD&T drafting for industry compliance.

-

Internship Seekers targeting roles in R&D, automotive design, or advanced manufacturing.

-

Course Syllabus

On a daily basis we talk to companies expert in these domains to fine tune our curriculum. Here are the list of courses that are part of this program

Introduction to CAD/CAM and its role in manufacturing & product development

Brainstorming final year project ideas (mechanical design, automation, fixtures, molds, etc.)

Understanding design specifications and standards

Setting goals: 3D Modeling, Simulation, CAM, G-code generation

Deliverables:

Finalized project title

Defined product specifications

Design brief

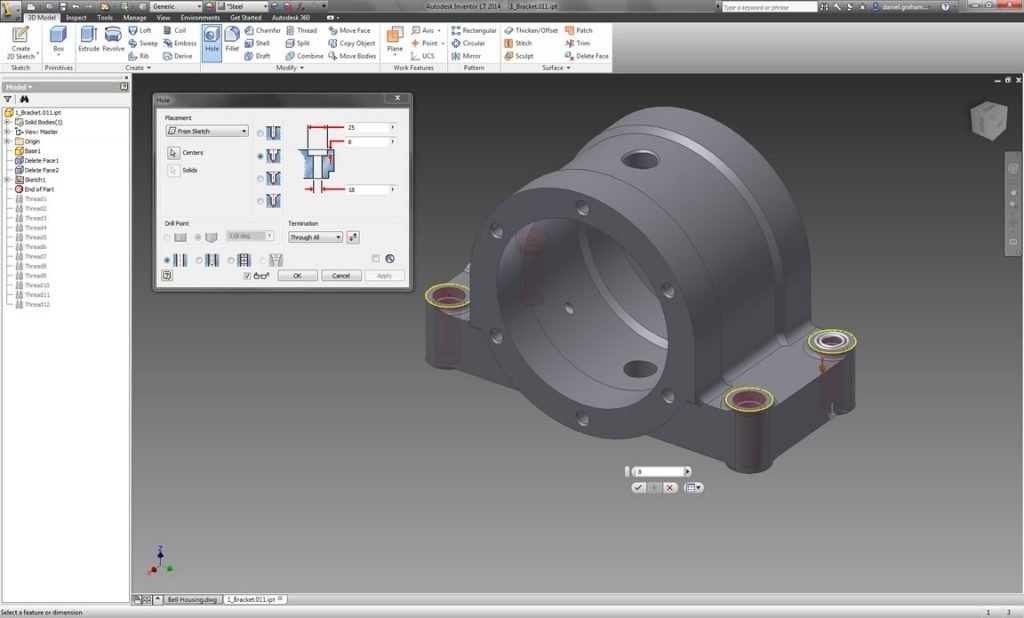

2D sketching and constraints

Creating 3D models using extrusion, revolve, sweep, loft

Design intent, parametric modeling

Design for manufacturing (DFM) principles

Deliverables:

3D models of individual components

Design tree with annotations

Mating parts, interference checks, and motion constraints

Creating a complete product assembly

Design validation using animation or exploded views

BOM (Bill of Materials) generation

Deliverables:

Assembly model (.sldasm, .f3d, etc.)

Animation video (optional)

Creating 2D drawings from 3D models

Dimensioning, GD&T basics, title blocks

Exporting drawings as PDF/DXF for manufacturing

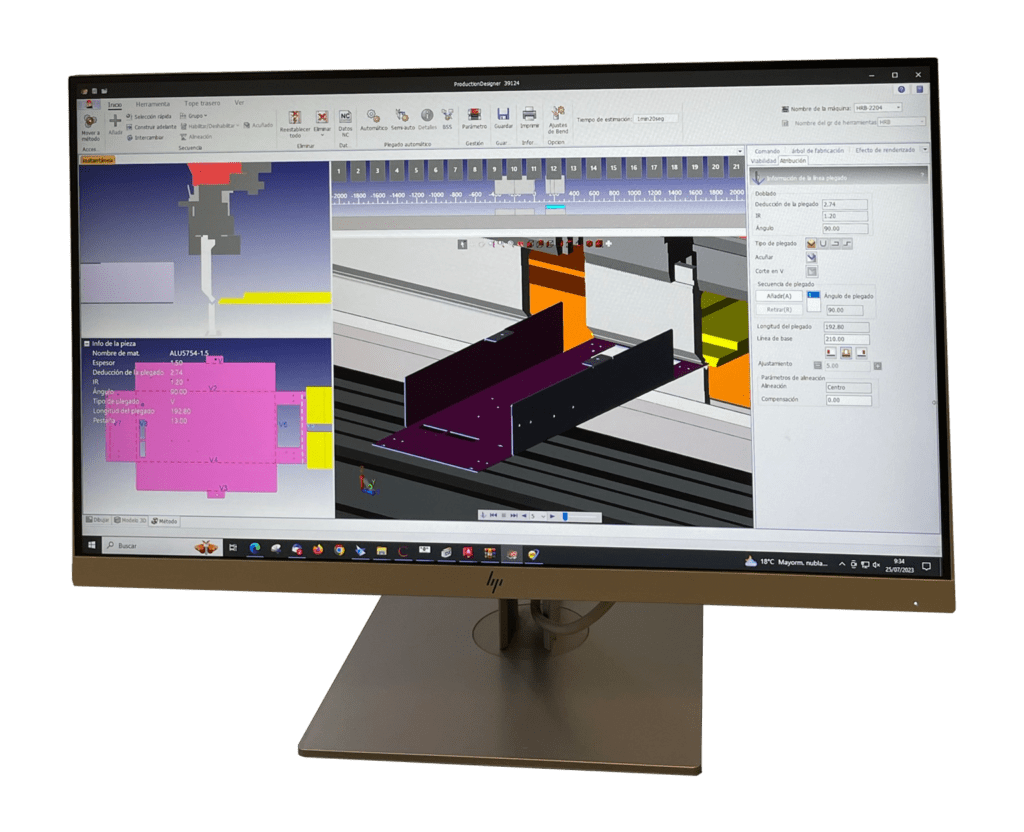

Sheet metal design (optional topic)

Deliverables:

Final 2D drawing sheets

Manufacturing-ready PDF drawings

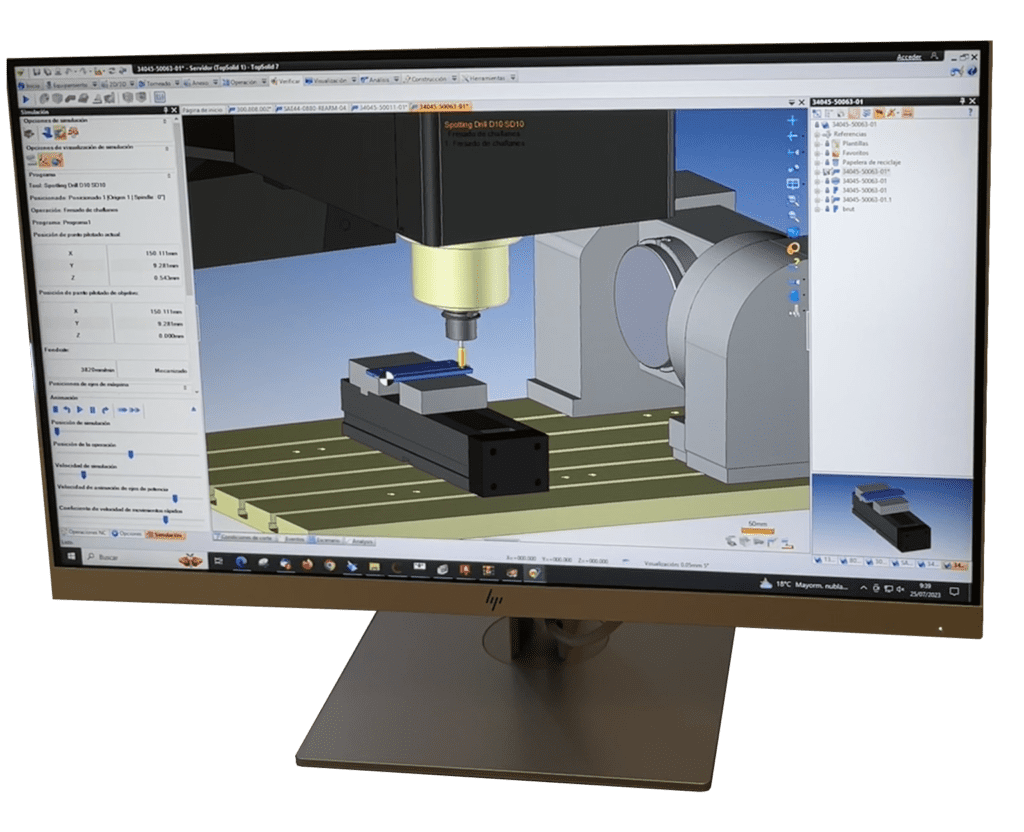

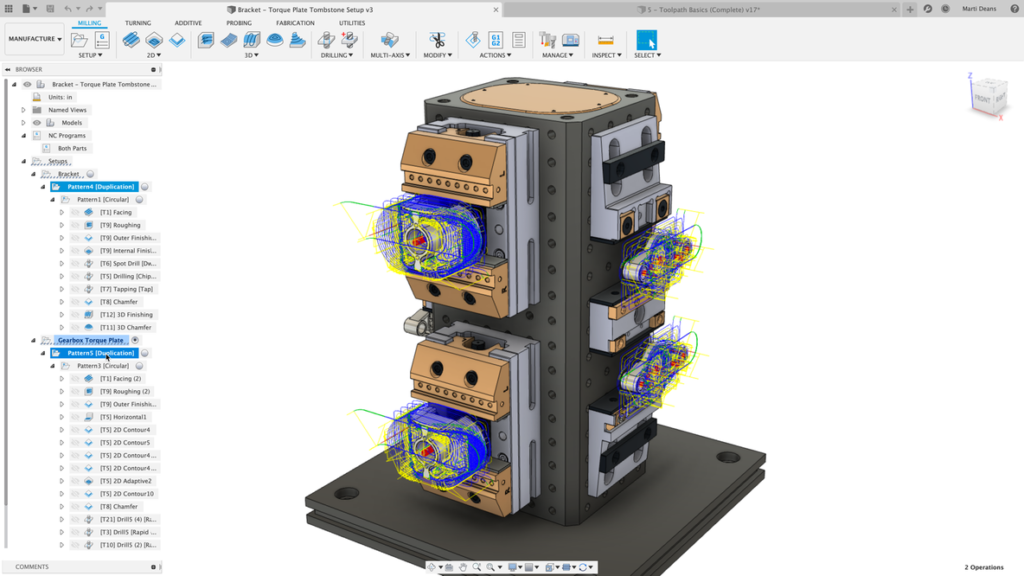

Introduction to CAM software (Fusion 360 CAM, Mastercam, or NX CAM)

Setting up stock, tools, toolpaths (2.5D milling, contour, pocket)

Work coordinate system (WCS) and tool libraries

Toolpath simulation and verification

Deliverables:

CAM toolpath files

Setup sheets

- Post-processing toolpaths into G-code

- CNC code interpretation (G0, G1, M-codes)

- CNC machine types and axes

- Safety and best practices in CNC simulation

- Deliverables:

G-code file for a sample component

Machine setup report (virtual)

- Report formatting: Abstract, methodology, design process, output

- Explaining part selection, material choice, and design changes

- Integrating CAD models, drawings, CAM screenshots into report

- Deliverables:

Full draft of final report

Image package (renders, screenshots)

Final PPT slide creation

Mock viva with project walkthrough

Feedback on report and presentation

Optional: Project display certificate

Deliverables:

Final report (PDF/DOC)

Final PPT (with embedded animations/renders)

Certificate of completion

Book Now

Sign Up Now

Student Reviews

Our Recent Student Reviews

"This mentorship turned my vague design ideas into a professional CNC-machined prototype. The live CAM demos in Fusion 360 were a game-changer!"

Aisha Khan, NIT Surathkal

Mechanical Engineering

"The CAM modules transformed my theoretical knowledge into hands-on G-code expertise. My project on automotive suspension arms is now part of my portfolio!"

Rohan Verma, VIT Vellore

Automotive Engineering

"As a civil engineer, I never thought I’d design medical devices! The 1:1 mentorship helped me pivot into product design effortlessly."

Priya Joshi, IIT Bombay

Civil Engineering

"My college lacked CNC machines, but the virtual CAM simulations and G-code walkthroughs made me industry-ready!"

Arjun Mehta, BITS Pilani

Aerospace Engineering

Got more questions?

Talk to our Team Directly

Please fill in your number & an expert from our team will call you shortly.