In the realm of evaporator design, Computational Fluid Dynamics (CFD) analysis emerges as an indispensable tool, providing a detailed and dynamic understanding of fluid behavior within the system. This advanced simulation technique allows engineers to delve into the intricate nuances of heat and mass transfer, enabling a comprehensive optimization of evaporator performance.

CFD Analysis in Evaporator Design:

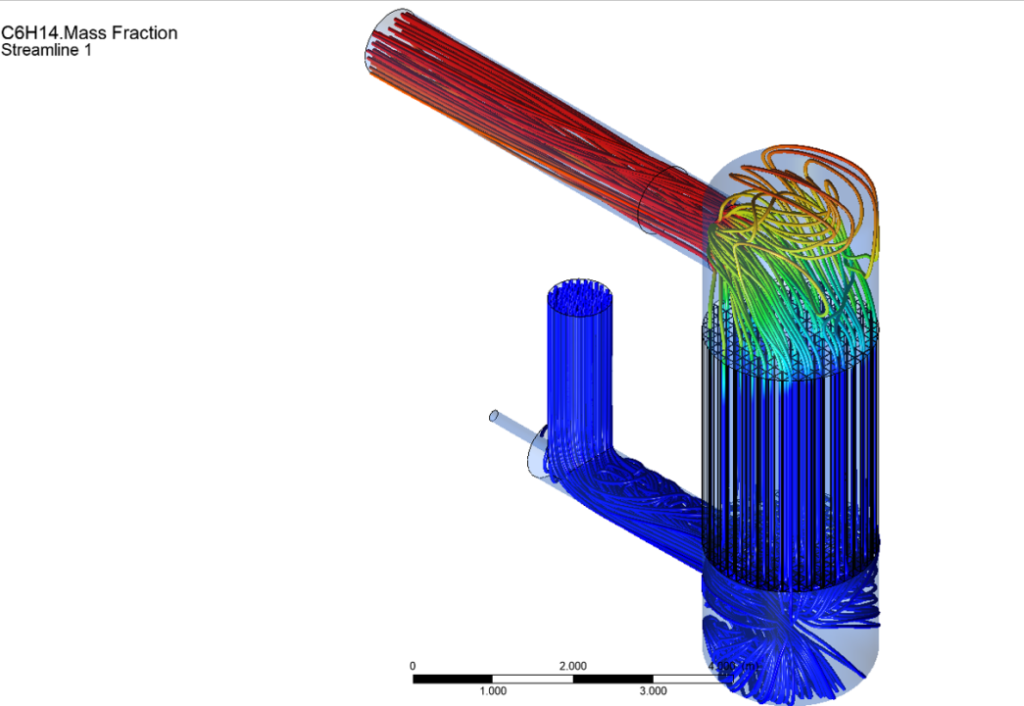

1. Fluid Dynamics Visualization: CFD simulations provide a visual representation of fluid flow patterns, temperature gradients, and pressure distribution within the evaporator. This intricate visualization aids engineers in identifying potential areas of concern and understanding the dynamics of the heat transfer process.

2. Heat Transfer Analysis: Evaporators rely on efficient heat transfer, and CFD allows engineers to analyze this crucial aspect in great detail. By inputting various parameters such as fluid properties, temperature differentials, and system geometries, the simulations offer insights into heat distribution, highlighting areas where modifications can enhance overall efficiency.

3. Identifying Hotspots and Inefficiencies: Through CFD analysis, engineers can pinpoint hotspots or areas of inefficiency within the evaporator system. This includes regions with excessive heat concentration, uneven temperature distribution, or inefficient fluid flow, allowing for targeted modifications to rectify these issues.

Cost Reduction Opportunities:

1. Virtual Prototyping: CFD analysis serves as a virtual prototype, allowing engineers to experiment with design modifications without the need for physical prototypes. This not only accelerates the design iteration process but also significantly reduces the costs associated with manufacturing and testing.

2. Operational Optimization: CFD simulations enable engineers to optimize operational parameters, such as flow rates, temperature settings, and system configurations, to maximize efficiency. This proactive approach minimizes energy consumption, contributing to long-term cost reduction by improving overall system performance.

3. Innovative Design Solutions: Leveraging CFD insights, engineers can explore innovative design solutions that enhance evaporator efficiency. This may include optimizing coil configurations, exploring alternative materials, or introducing novel heat exchange mechanisms. Such innovations not only improve performance but can also lead to substantial cost savings over the lifecycle of the evaporator system.

Conclusion:

Incorporating CFD analysis into evaporator design is akin to unlocking a treasure trove of insights. Beyond the visualizations and simulations, CFD empowers engineers to make informed decisions, streamline processes, and implement targeted modifications that lead to enhanced efficiency and substantial cost reductions. As industries increasingly embrace these advanced simulation techniques, the future of evaporator design is poised to be more efficient, economical, and sustainable than ever before.